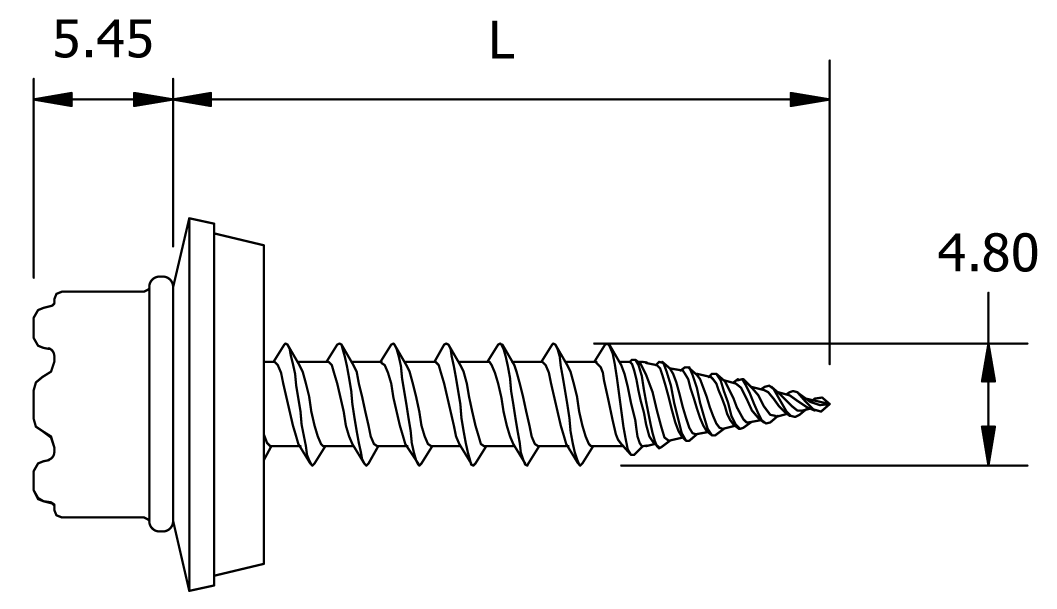

Product data of KINGI® metal roofing screws

| Length of the screw | 25 mm or 32 mm | |

| Material of the screw | C1022 or equal | Core and surface hardened with non-alloy steel. |

| Electrical zincing | 12 µm | Gives cathodic protection for the steel. |

| Pre-treatment | Silane | Maximizes the adhesion of the paint and corrosion resistance. |

| Prime coating | Epoxide polyester, 60 µm | Contains chemical components to improve the adhesion of the paint and slows down corrosion |

| Top coating | Polyester, 60 µm | The top coating is developed for building facades for appearance and corrosion resistance. |

| Screw base | CrownD-head | Fits firmly into the socket and enables a firm installation. The EU model protected design helps water to flow away from the top part of the screw reducing the risk of corrosion. |

| The metal part of the washer | 1mm thick aluminium alloy EN AW 5052 H32 | Maximum mechanical durability and corrosion resistance even in the harshest conditions. |

| Gasket part of the washer | EPDM 2,5 mm, 70 Shore A | Optimized for good, firm installation, and a long lifecycle. |

| Screw tip | FastFX™ -screw tip | The special screw tip design allows fast penetration of the sheet and firm hold on the metal sheet. The special tip does chip the metal sheet, and it will stay steady during the installation. |

Package data

Screw size: 4.8 x 25 or 32

Sales package: 250 screws

Wholesale package: 3000 screws

Euro-pallet: 60 wholesale packages, total 180 000 screws

Minimal delivery batch: 1 pallet / color

Stock Colors

Six basic colors.

You can also ask for customized colors.

Corrosion resistant even in corrosion class c4

When you want the whole color coated metal roof to last long, the metal roofing screws must last as long as the metal steel sheet. The KINGI® metal roofing screw is a coated steel screw that lasts, even in harsh weather conditions thanks to its unique patented Durabl3-coating system. The coating system of the KINGI® screw is produced according to the DIN 55634 standard and meets the requirements of corrosion classes C1–C4.

ISO 9001 – Quality Certificate

ISO 9001 – Quality System

The whole production process is tested and certified according to the ISO 9001 –quality standard. Quality assurance of the product is in accordance with standards SFS-EN ISO 3269 and SFS-EN ISO 10666:1999. Product quality is monitored continuously with the corrosion tests conducted by third-party research bodies.

Warranties

20 years appearance and rustfree warranty

30 years leakage free warranty

50 years technical warranty